Key Differences Between Renewable Diesel and Biodiesel

Renewable diesel, also known as “green diesel,” is catching up to biodiesel in popularity, and there have been major increases in its production, distribution, and availability in recent years. Both biodiesel and renewable diesel are good alternatives to petroleum diesel, complying with U.S. Renewable Fuels (RFS) mandates, reducing environmental impact, and lessening dependence on fossil fuels. They are also both great choices to boost the efficiency of your boiler room.

Each option is produced using a different method and comes with its own unique characteristics. Below, you’ll find information about the key differences between Renewable Diesel and Biodiesel and what each brings to the table.

Key Differences Between Renewable Diesel and Biodiesel: What is Biodiesel?

Biodiesel, also known as Fatty Acid Methyl Ester (FAME), is produced using a process called transesterification, which transforms fats and oils into fatty acid alkyl esters by reacting them with alcohols and catalysts (often methanol). For every 100 lbs. of vegetable oil or animal fat and 10 lbs. of methanol, this process can create 100 lbs. of biodiesel and 10 lbs. of glycerol.

Biodiesel is a popular choice for heating systems because it reduces reliance on fossil fuels and produces significantly lower carbon emissions than alternatives like gas, oil, coal, and petroleum diesel.

In comparison to petroleum diesel, biodiesel comes with several advantages, including:

- Reduced CO₂ emissions – Combustion from biodiesel produces significantly lower levels of greenhouse gases.

- Non-Toxicity and Biodegradability – If a biodiesel spill occurs, it’s much less harmful to the environment than a petroleum diesel spill.

- Renewability – What is biodiesel made of? Instead of fossil fuels, biodiesel is made from renewable resources like vegetable oils, recycled grease, and animal fats.

- Lubricity – Able to lubricate better than petroleum diesel, biodiesel can extend the life of equipment and improve performance, reducing wear and tear over time.

- Higher Cetane Number – This allows for enhanced performance and easier starting.

Despite these advantages, biodiesel isn’t perfect and does come with some downsides in comparison to petroleum diesel, including:

- Oxygen Content – Because biodiesel contains oxygen, it offers around 7-13% less energy per volume in comparison to petroleum diesel. As a result, burner adjustments are often needed to maintain a correct air-fuel ratio.

- Storage Shelf Life – Biodiesel’s oxygen content can reduce the amount of time it can be stored before corrosion occurs due to oxidation. Its chemical makeup can also make it more vulnerable to microbial fouling over time.

- High Freeze Point – The freeze point of biodiesel, or its cloud point, is between 30 to 68 °F depending on the feedstock, while the freeze point for petroleum diesel is around 16 °F. When biodiesel freezes, it first forms visible crystals and undergoes “gelling,” which means it solidifies and can’t flow properly.

It’s also important to note that biodiesel often must be mixed with petroleum diesel. For instance, B30 is 30% biodiesel and 70% petroleum diesel. While the necessity of blending for certain applications may be a complication at times, it allows for compatibility with most diesel-powered machines.

B100 Diesel: An Innovative Alternative to Blended Diesel

B100 diesel is a type of biodiesel that isn’t mixed with petroleum diesel. It’s biodiesel in its 100%, pure form. In comparison to blended biodiesel, it offers some key benefits including:

- Lower emissions

- Cleaner and more efficient burning

- Ability to reduce buildup in fuel systems

- A higher flashpoint, which means it’s less hazardous and less likely to ignite under pressure

For boiler operations, B100 can often be used in current systems with minor upgrades. For instance, employing B100-compatible solenoid valves can often allow for a seamless transition to pure biodiesel.

Key Differences Between Renewable Diesel and Biodiesel: What Is Renewable Diesel?

You’ve probably heard of it as a new fuel alternative, but you may be wondering, “What is renewable diesel?” Like biodiesel, renewable diesel is made from feedstocks like vegetable oils, recycled grease, and animal fats. It’s produced through a different process than biodiesel, however, and its production results in a unique profile and benefits.

Renewable diesel is commonly produced using hydroprocessing or hydrotreating. This process involves reacting fat or oil with hydrogen under high temperature and pressure in a catalytic reactor. This is quite similar to the production method for petroleum diesel. The biggest difference is that fossil fuel is swapped out with a more sustainable feedstock.

In comparison to petroleum diesel, renewable diesel offers many of the same benefits as biodiesel, including reduced carbon emissions, biodegradability which lessens the impact of spills, higher cetane number, and enhanced lubricity. Like biodiesel, renewable diesel is also an excellent choice for compatible heating systems.

In addition to these perks, renewable diesel outshines biodiesel in several ways, including:

- Hydrocarbon Fuel Status – Renewable diesel is made up of hydrogen and carbon, just like petroleum diesel. This allows it to be used as a drop-in replacement. Unlike biodiesel, renewable diesel doesn’t have to be blended to be used as fuel in many applications.

- Longer Shelf-Life – Renewable diesel isn’t subject to oxidation in the same way biodiesel is, and it can be stored for longer periods without degrading or leading to undesirable outcomes like microbial fouling and storage tank corrosion.

- Better Cold Weather Capabilities – Like petroleum diesel, renewable diesel flows better and doesn’t crystal or gel in cold temperatures. Its lower cloud point can be a major plus.

- Higher Energy Per Volume – While biodiesel offers around 7-13% less energy per volume than petroleum diesel, renewable diesel offers around 4% less, which is a seemingly small but significant difference. In the case of renewable diesel, the burner air-fuel ratio is close enough that there’s no need for burner re-tuning.

- Lower NOx Emissions – While both biodiesel and renewable diesel produce less air pollution than traditional diesel, the latter offers even lower NOx emissions, which translates to cleaner air and an even more minimal environmental effect.

The capital costs of renewable diesel production can be higher than those associated with biodiesel production. This is because crude oil refining technology and equipment are used to produce renewable diesel. While this can be a downside, a benefit of renewable diesel production is that it is easier to scale and integrate into existing refinery operations. Portions of crude oil refineries can be converted into renewable diesel production facilities, or refineries can be entirely converted in a move away from petroleum.

Get a FREE Consultation on Biofuel Boiler Room Systems Now!

Call us at 631-331-0215 or fill out the form below and one of our representatives will get back to you shortly.

Available products that are compatible with biofuels:

Thermal Leverage Tri-fuel Boiler

Fulton Vantage Boiler

Fulton VMP Boiler

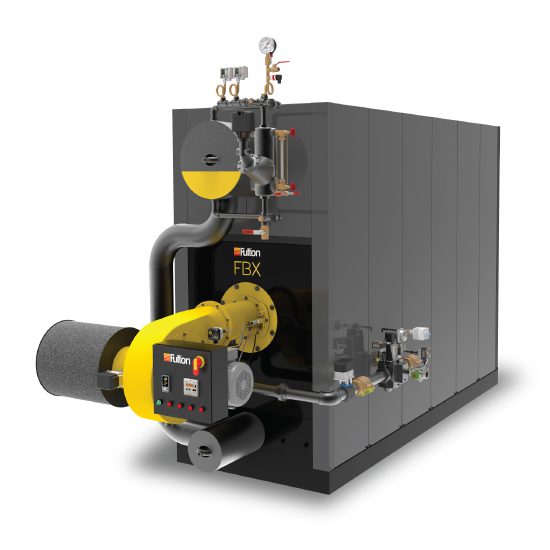

Fulton FBX Boiler

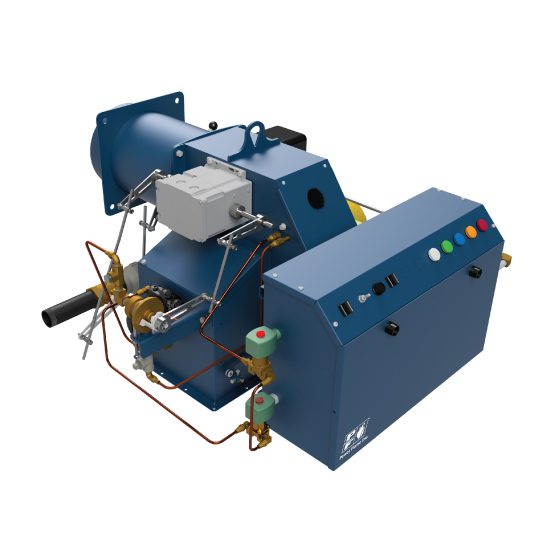

Power Flame C Burner

Power Flame CMAX Burner

Get a FREE Consultation on Biofuel Boiler Room Systems Now!

Call us at 631-331-0215 or fill out the form below and one of our representatives will get back to you shortly.

Conclusion

The same feedstocks, including organic fats, grease, and oils, can be used to make both biodiesel and renewable diesel. Biodiesel’s simple transesterification production process results in an eco-friendly alternative to petroleum diesel, but it often needs to be blended with petroleum diesel to be used as fuel. B100, which isn’t blended, is a viable alternative, but modifications may be needed for compatibility with existing boiler systems.

Renewable diesel, on the other hand, doesn’t need to be blended with petroleum and can serve as a drop-in replacement. It also offers many of the same advantages as biodiesel without some of the drawbacks like high oxygen content and a high freeze point. Renewable diesel outperforms biodiesel in some critical areas, boasting a longer shelf-life, lower cloud point, superior performance in cold weather, and higher energy per volume. If your current boiler room equipment is fueled by petroleum diesel, you can make the switch to renewable diesel without any upgrades or modifications and start lowering emissions right away.

With its many benefits, oil producers are increasingly investing in renewable diesel. It’s now being consumed at a much higher rate than it was just a few years ago, and it’s becoming much more widely available in states like New York. As production, access, and use increase, it’s highly possible that renewable diesel will surpass biodiesel in popularity, and it will likely take on a more prominent role in reducing emissions in the years to come. There’s a significant amount of potential for its applications to reduce emissions in commercial and industrial heating, and it will be exciting to see the part it plays in the coming years.