Looking for more information, a free consultation, or a project quote?

Call us at 631-331-0215 or fill out the form, and one of our experts will get back to you shortly.

When your boiler project demands nothing less than a seasoned, trusted resource who will fulfill your critical boiler room infrastructure requirements now and tomorrow, you need ATI of NY.

At ATI of NY, we are proud to be the manufacturer's representative for some of the leading boiler room and combustion-related product manufacturers in the world.

ATI of NY serves and collaborates with each touchpoint to ensure seamless design and function, from project conception through the life of your equipment.

From multi-family to hospitality, healthcare to food & beverage, ATI's expertise extends to a dozen industries and continues to expand it's reach into even more.

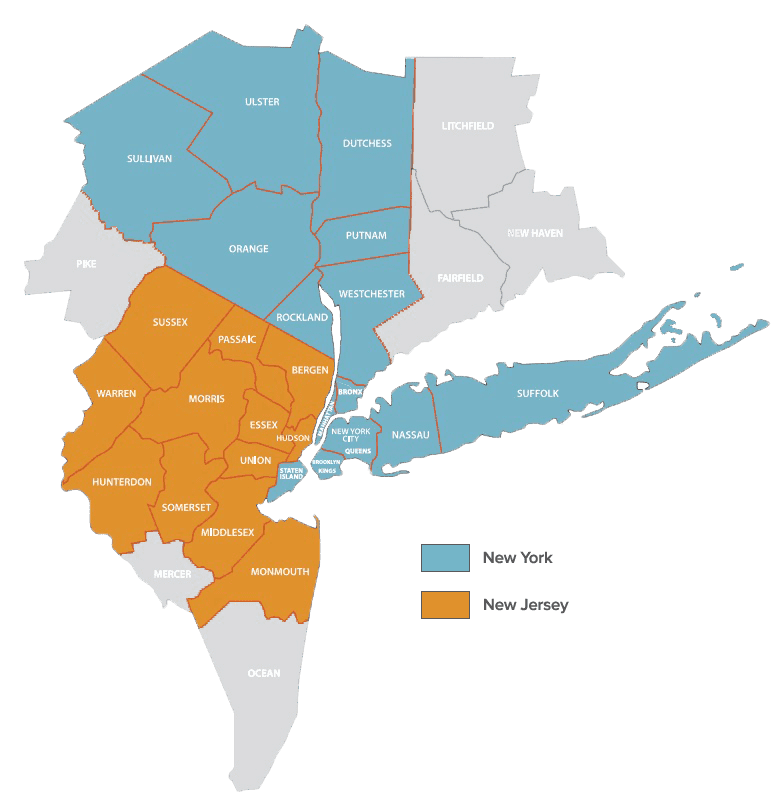

ATI of NY is proud to be the manufacturer's representative for world leading commercial heating industry brands in the New York Metropolitan area.

Partner with ATI of NY for all your heating and combustion system design support needs.

Elevate your team’s industry knowledge without leaving the office and earn valuable PDH credits with ATI’s engaging Lunch & Learn seminars. Our seminars offer in-depth insights into the latest industry trends and requirements.

We offer custom prefabricated engineered assemblies with the purchase of any boiler system. Manufactured in the USA, these military-grade platforms deliver stability, portability, protection and a smaller footprint for large-scale industrial equipment.

ATI of NY is proud to partner with National Business Capital to provide financing solutions for your projects. This partnership ensures fast, flexible funding options tailored to your business needs, helping you stay on schedule and within budget.

Our goal is to provide you with efficency upgrades so your business can operate at peak performance. Seee how we've helped clients reach their efficiency goals specific to their application needs.

Our factory-certified technical services team provides end-to-end critical building energy services on a variety of commercial and industrial heating systems.

The Lockwood Products Model SSL deaerator is a low profile spray scrubber deaerator. The vessel includes a deaerating section that is integral to the horizontal storage section. Lockwood Model SSL deaerators are designed to reduce the dissolved oxygen content of the feedwater to no more than 0.005 cc/liter (7 ppb) and reduce the titratable free carbon dioxide to zero. To do this, the feedwater goes through a two-stage mechanical deaeration process. The incoming water is injected into a steam atmosphere at the top of the deaerator via stainless steel spray nozzles. The nozzles create a hollow conical spray pattern which results in a large surface area allowing rapid heating of the water. As the water approaches saturation temperature, the dissolved gases are released by the water and carried away by the steam. A majority of the corrosive gases are removed before the water strikes any steel surfaces within the deaerator. The non-condensable gases are then vented from the deaerator through a stainless steel vent pipe located near the top of the vessel. A valve and orifice are used to control the vent rate. The hot deaerated water then passes through steam scrubber section of the deaerator. High velocity steam is forced through the water causing vigorous scrubbing of the remaining dissolved gasses.

Call us at 631-331-0215 or fill out the form, and one of our experts will get back to you shortly.

We offer custom prefabricated engineered assemblies (packaged skids and enclosures) with the purchase of any boiler, heating, cooling or water system. Manufactured in the USA, these military-grade platforms deliver stability, portability, protection and a smaller footprint for large-scale industrial equipment.