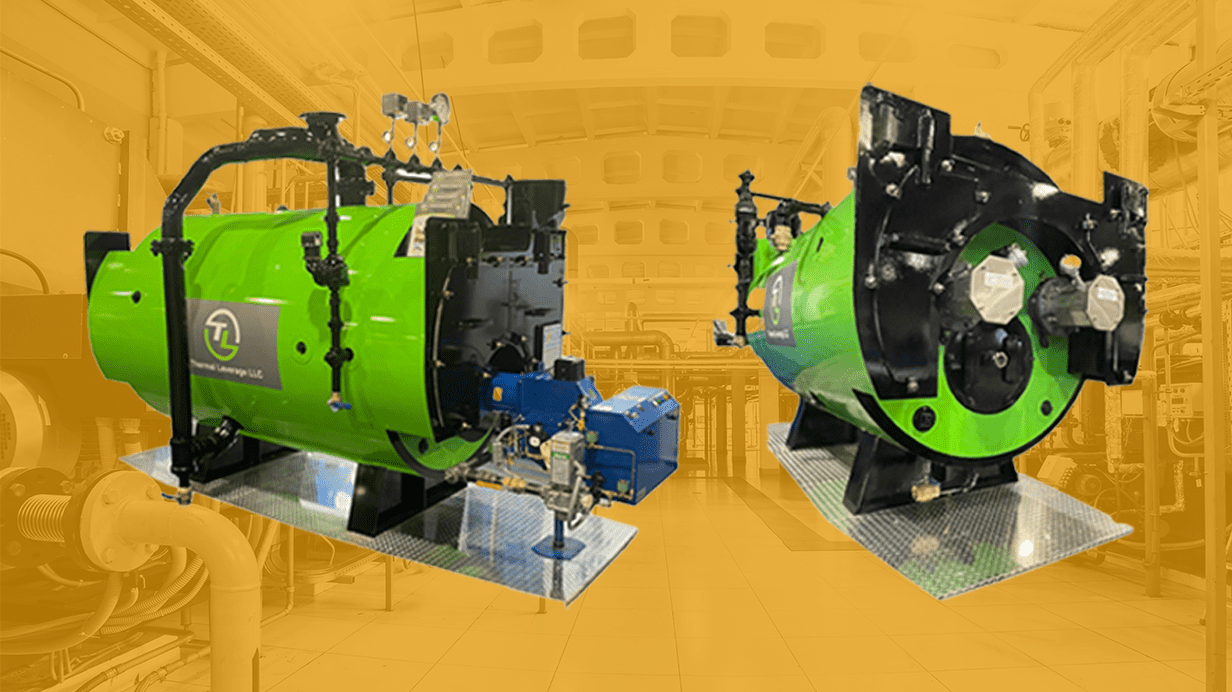

An Informative On-demand Webinar on Sustainability and Compliance Sponsored by: ATI and Power Flame Fueling the Future: Biodiesel's Rise in Home Heating and the Green Revolution Right now, more than 5 million homes and businesses in the U.S. use liquid fuels for...