The Rise of CO₂ Heat Pumps: How HVAC Is Evolving to Meet Global Sustainability Goals

Global trends toward sustainability compel the HVAC industry to replace outdated equipment and embrace new technology that supports Net Zero initiatives. With mounting concerns about greenhouse gas (GHG) emissions and the gradual discontinuation of high-global-warming-potential (GWP) refrigerants, the industry is faced with a need to adopt sustainable alternatives. CO₂ (R744) heat pumps have surfaced as a top solution among available options, offering major advantages, both operationally and environmentally.

Switching to Low-GWP Refrigerants

Recent regulatory changes in the U.S. underscore the shift toward more sustainable refrigerants. Spearheaded by the Kigali Amendment to the Montreal Protocol, the national phase-out of hydrofluorocarbons (HFCs) by 2050 and the prohibition of high-GWP refrigerants starting in 2025 mark significant milestones in reducing GHG emissions. These changes necessitate a transition toward refrigerants with lower global warming potential (GWP), such as carbon dioxide (CO₂).

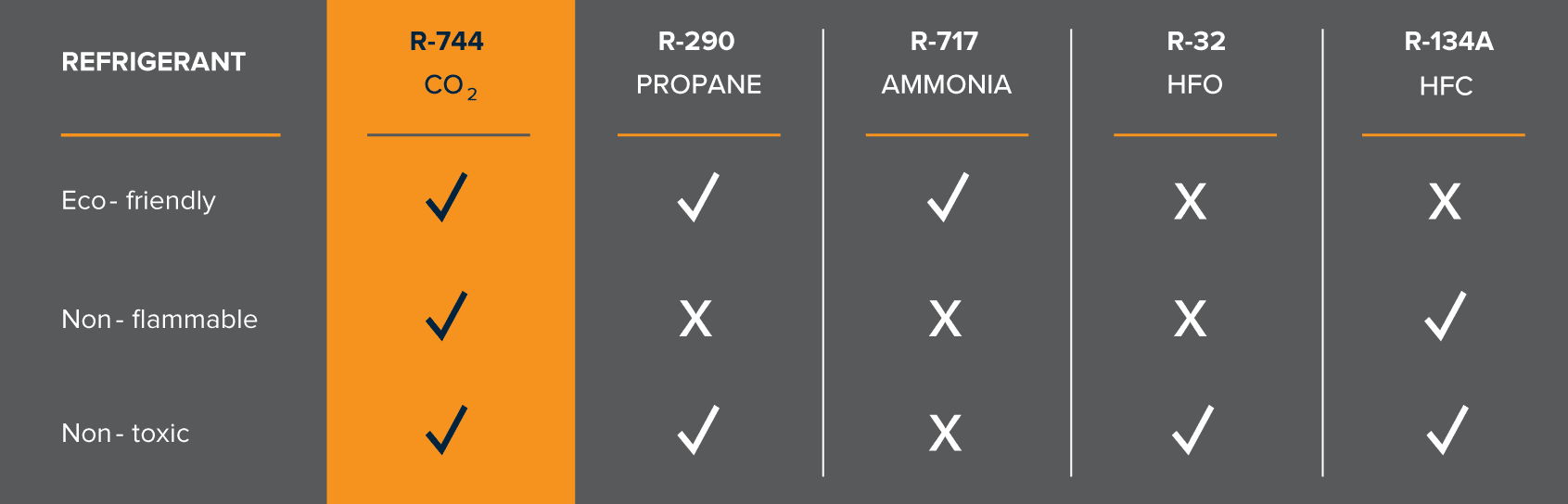

Refrigerants with low global warming potential (GWP) are disrupting the landscape of heating and cooling systems, offering a viable way to address climate change and satisfy regulatory requirements in the U.S. and around the world. Chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs), and hydrofluorocarbons (HFCs) used to be the industry refrigerant standards. They allow for smooth operation, are non-flammable, and are non-toxic. However, they are also considered greenhouse gases, and their long-term use has a considerable, negative effect on the environment.

Natural and environmentally benign refrigerants, such as carbon dioxide (CO₂), hydrocarbons like propane and isobutane, and ammonia, have surfaced as leading alternatives in recent years. In addition to being more eco-friendly, they also offer more energy efficiency in most applications, resulting in lowered operational expenses over time. Transitioning to these alternatives, however, does require system upgrades, modifications, and training to ensure proper and hazard-free operation, handling, and disposal.

CO₂ (R744) heat pumps from leading manufacturers like Dalrada are particularly promising for enhancing the sustainability of boiler room systems to comply with regulations and reduce dependence on HFCs. Additionally, these solutions help meet the efficiency and emissions requirements in major U.S. cities, including NYC, where Local Law 97 (LL97) recently went into effect.

CO₂ Heat Pumps Mechanics

CO₂ heat pumps run using a transcritical cycle, a process that involves the refrigerant passing through both subcritical and supercritical phases. The transcritical cycle allows CO₂ heat pumps to efficiently generate both heating and cooling, making them well-suited for a variety of applications.

CO₂ Heat Pump Operation Cycle Components

- Compression: CO₂ is compressed under high pressure, substantially increasing its temperature.

- Condensation: Pressurized CO₂ passes through a condenser, where it transfers heat to water to raise its temperature.

- Expansion: The CO₂ expands, lowering its pressure and temperature.

- Evaporation: The cold CO₂ absorbs heat from cold water in the evaporator.

In the case of Dalrada DCE Series Commercial heat pumps, this cycle allows CO₂ to produce water temperatures up to 194°F (90°C) while also generating cold water at the same time. For applications that require both heating and cooling, this is a major plus.

Advantages of CO₂ Heat Pumps

The most advanced CO₂ heat pumps bring with them several benefits in comparison to other heating and cooling systems, notably in terms of versatility, efficiency, and environmental effects. Below are some of their advantages:

- Energy Efficiency: CO₂ heat pumps achieve a high coefficient of performance (COP) due to their operation capabilities at high pressures, translating to energy conservation.

- High Temperature Capabilities: Some CO₂ heat pumps can produce hot water at temperatures up to 194°F (90°C). This makes them ideal for a variety of industrial applications.

- Environmental Compatibility: With zero ozone depletion potential (ODP) and a Global Warming Potential (GWP) of 1, CO₂ is a natural refrigerant that supports global aims to reduce GHG emissions.

- Simultaneous Heating and Cooling: The ability to produce hot and cold water at the same time allows for flexible and efficient operation.

- Zero Combustion: Heating and cooling without combustion distinguish advanced CO₂ heat pumps from alternatives.

- Decarbonized Heat: In comparison to traditional boilers and other heat systems, CO₂ heat pumps reduce carbon emissions dramatically.

- Reduced Dependence on Fossil Fuels – They can replace older heating and cooling equipment that requires the burning of fossil fuels.

Additional Specific Benefits of CO₂ (R744) Refrigerant

CO₂’s unique properties as an innovative, natural refrigerant also offer additional key benefits, including:

- Non-Toxic and Non-Flammable Profile: Reducing risks in the case of leaks or during improper disposal, CO₂ is safer poses fewer safety issues than other natural refrigerants.

- High Operating Pressures: While conventional refrigerants often require the use of specialized components to withstand high operating pressures, CO₂ can operate under significant pressure.

- Wide Temperature Range: CO₂ refrigerant can be used for both low-temperature (freezing and deep freezing) and medium-temperature (commercial refrigeration and a/c) applications.

Real-World Uses of CO₂ Heat Pumps

CO₂ heat pumps are trending and poised to continue to have a positive impact in various locations, including:

- Data Centers: Data centers, which generate considerable amounts of waste heat, can use CO₂ heat pumps to repurpose this heat for other applications while simultaneously cooling critical equipment. This reduces energy expenditures and enhances overall system efficiency.

- Hospitals: CO₂ heat pumps provide hot water for sanitary use and cold water for important areas, such as operating rooms, enhancing energy efficiency and lowering operational costs.

- Shopping Centers: With the help of CO₂ heat pumps to simultaneously heat water and cool retail spaces, shopping centers can optimize their energy consumption.

- Hotels: CO₂ heat pumps can produce domestic hot water while simultaneously providing cooling for HVAC systems. This dual functionality lowers energy consumption and while boosting operational efficiency.

- Industrial Laundries: Large industrial laundry centers can employ CO₂ heat pumps to produce the large amounts of hot water required for washing. The leftover cold created by the system can be used to keep work areas cool.

- Meat Packing Facilities: CO₂ heat pumps are particularly useful in the meat industry, where they can heat water for cleaning processes while controlling the temperature in the refrigerated spaces where meat is stored.

- Office Buildings: CO₂ heat pumps are well-matched for the heating and cooling requirements of large buildings that house business offices.

- Apartment Buildings: Apartment buildings need substantial heating and cooling capabilities for the varying needs of tenants, and high-temperature heat pumps can handle the job.

Limitations and Challenges

While CO₂ heat pumps come with many benefits and their adoption is becoming more widespread, they also can pose certain challenges, including:

- Up-front Costs: In some cases, CO₂ heat pumps may require higher initial investment costs in comparison to traditional systems.

- Temperature Limitations: Some CO₂ heat pumps are not efficient with water returns above 104°F (40°C). This is fortunately not always the case with more advanced heat pump models.

- Incompatibility for Cold-Only Applications: CO₂ heat pumps are not engineered for refrigeration only.

- Simultaneity Needs: CO₂ heat pumps necessitate the simultaneous use of heat and cold to function properly. System efficiency can become compromised in applications without this simultaneity.

Tackling Challenges in Industrial Building Applications

Renovating industrial buildings to incorporate CO₂ heat pumps may cause certain difficulties to arise, particularly when these buildings were originally designed to use thermal energy in the range produced by gas boilers. The terminals and distribution pipes in such buildings are designed for high temperatures, making the introduction of low-temperature heat pumps inefficient.

To address this issue, heat pumps capable of operating at higher temperatures, comparable to traditional gas boilers, are required. For example, Dalrada’s DCE HT range of heat pumps can achieve temperatures between 158°F and 176°F (70-80°C) using advanced refrigerants such as propane (R290) and R513A. These heat pumps offer a modern, efficient heating solution without necessitating structural renovations.

CO₂ Heat Pumps Lead the Charge in HVAC Sustainability

The growing adoption of CO₂ heat pumps is a significant step forward in the HVAC industry’s journey toward sustainability. CO₂ heat pumps provide a viable solution for reducing GHG emissions and complying with evolving and increasingly stringent regulatory standards. As the U.S. and the rest of the world continue to prioritize eco-friendly solutions, CO₂ heat pumps are poised to play a major role in shaping the future of heating and cooling, contributing to a greener and more eco-conscious future.

By choosing Dalrada heat pumps, you can provide your clients with a reliable, cost-effective, and environmentally friendly solution. Contact ATI today at 631-331-0215 or fill out the form to learn more about our heat pump products and how they can benefit your next project.

Looking for more information, a free consultation, or a project quote?

Call us at 631-331-0215 or fill out the form, and one of our experts will get back to you shortly.

DCT One Series Heat Pump

DCE Heat Pump