How Can Brewmasters Choose the Best Boiler for a Brewery?

Looking for the best boiler for your brewery? At Applied Technologies of New York, we’ll guide you to the ideal boiler for your craft brewery and carefully explain all of your options along the way.

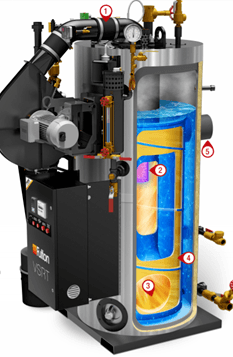

While we offer equipment from the world’s leading manufacturers, we regularly suggest Fulton’s boilers as the best boiler for your brewery. Why? Continue reading to learn more about why the Fulton Vertical Spiral Rib Tubeless (VSRT) Steam Boiler is the best boiler for a brewery.

To give you a quick preview, these are the VSRT’s key features:

- 86% Efficiency: – highest efficiency of any boiler on the market without an economizer

- High Turndown: 10:1 turndown ratio, which is unheard of in a steam boiler

- Tubeless Design: Never needs to be retubed

- Industry-Leading Warranties: 10 Year Boiler Warranty + 5 Year Burner Warranty – No other manufacturer offers this.

- Superior Steam Quality: 99.75% pure dry steam highest you’ll find anywhere

- Highest Vertical Capacities on the Market: Capacities up to 250 HP in a vertical configuration

- Ultra Low-NOx: Included standard

A Look Inside the Vertical Spiral Rib Tubeless Brewery Boiler Design

The VSRT features several technologies that make it the ideal solution for brewers. The patent-pending spiral rib heat exchanger uses state-of-the-art technology to achieve industry-leading heat transfer rates. The spiral rib design allows the boiler to have an exceptionally compact footprint and achieve maximum heat transfer.

- Air/fuel mixture enters into the VSRT combustion chamber.

- The optimized burner fires downward, which works to prevent burner plate impingement.

- Combustion gases transition in a downward position from the combustion chamber to the spiral heat exchanger.

- The flue gases will spiral upward being channeled through the patent-pending heat exchanger.

- Flue gases leave the boiler.

Save Your Space for Creating Delicious Beer with the Craft Brewery Boiler

Regardless of your industry, the last thing you want to spend money on is wasted floor space. The more space taken up by your boiler equipment, the less space you’ll have for creating beer we always guide brewers toward boilers with the most compact footprint.

To accommodate this inherent need for space, we regularly guide brewers toward vertical boilers, like the VSRT. While horizontal boilers are positioned horizontally to the plane, vertical boilers are positioned erect. Vertical boilers are uniquely designed to save space and offer one of the most compact footprints available on the market today.

Fulton’s Boiler for Your Brewery Is Built to Last

One of the most common reasons boilers go kaput is because of boiler plate impingement. Flame impingement can cause a long list of issues — ultimately resulting in the detrimental compromise of the integrity of your boiler. Anytime the burner flame makes contact with the side of the furnace’s water walls or shell plate in water tube boilers, the result is corrosion on the shell/tubes plate at the flame interface.

This corrosion is further accentuated whenever heavier oils with higher contaminants are used. The products of combustion include compounds that will eat into the metal surface of the plate or shell. In addition, the increased metal temperatures can cause long-term or short-term overheating — depending on the stress distribution and extent of temperature variations. In short, the impingement from a burner will cause the backend of the boiler to wear out — oftentimes in less than five years.

Once the plate burns out, it will burn through the jacket, and the boiler is useless and dangerous. While the plate can sometimes be welded, welding a heating vessel will disturb the stamp. After the stamp is compromised, your boiler will no longer be in compliance and be illegal.

How Does Fulton’s VSRT Overcome Impingement?

Fulton’s VSRT boilers are uniquely designed to overcome boilerplate impingement. As shown in the diagram, Fulton’s VSRT boilers do not fire from the side of the boiler — it fires from the top and shoots the flame down the center to completely avoid the likelihood of impingement. You can see a visual of this flame arrangement by looking at #2 in the diagram above.

This unique design also allows the Fulton VSRT to achieve better heat efficiencies, much better heat transfer, and better performance. Most importantly, this innovative design means Fulton is willing to stand behind their products with better warranties, such as:

- A 10-Year Pressure Vessel Warranty

- A 10-Year Warranty with an Engineered System

- A 5-Year Burner Warranty

- No other boiler manufacturer is able to offer such a strong warranty.

Get Fulton’s Vertical Advantage in a Boiler for a Brewery

Why are Fulton’s boilers the preferred boiler for breweries? There’s no single answer to this question. The Fulton VSRT is the world’s first and only spiral rib tubeless design, which means it can transfer the most heat in the most compact space. Let’s look a summary of the advantages offered when you choose the Fulton VSRT boiler for your brewery:

- The VSRT boasts an exceptionally tall steam space and generous steam release area results in more than 99.75% steam quality.

- With a compact vertical footprint, up to a 30-HP VSRT will easily fit through a standard doorway.

- These vertical boilers save space and are exceptionally quick to heat, so you don’t waste energy waiting on the boiler to reach brewing temperatures.

- The VSRT will quickly get up to temperature and pressure to provide the application steam or heat required by brewers.

- The unique design of the VSRT negates the likelihood of boiler plate impingement from the flame.

- These boilers are top-of-the-line, so you don’t have to worry with water treatment or excessive maintenance.

- Fulton’s boilers are crafted from rugged industrial materials.

- Fulton’s VSRT delivers up to 86% efficiency with up to a 10:1 turndown ratio and NOx emissions below 20 ppm.

Contact ATI of New York for the Best Boiler for a Brewery

Choosing the best boiler for your brewery isn’t like purchasing other equipment. It’s vital the equipment you choose is specifically calibrated to meet the demand of your facility as well as your budget.

At ATI of New York, we bring decades of experience making the perfect match. Even if the Fulton VSRT doesn’t meet your needs and exceed your expectations, we’ll help you find the best boiler for your brewery.

Contact Applied Technologies of New York today to find the best boiler for your brewery.