Organization: NY Presbyterian Hospital – NYC

Engineer: Cosentini Associates

Contractor: HTS & Nelson Air

New York Presbyterian Hospital (NYPH) required a new high pressure steam plant to facilitate sterilization and humidity control for a new critical surgical process for spinal cord injury treatment. This vitally important project was time sensitive and had many challenges with respect to how and where to locate the equipment. A solution was created between HTS and ATI to construct a complete enclosure to be located on the roof of NYPH Hospital to house the boiler plant and accessories.

The requirement for the plant included high pressure steam boilers that were compact, reliable and capable of firing natural gas. The perfect answer was found in Fulton Model VMP high pressure steam vertical firetube boilers. The enclosure was built at HTS’s plant in Ontario Canada. All of the equipment was fabricated and tested at Fulton’s plant in Pulaski, NY and shipped to HTS for placement in the enclosure.

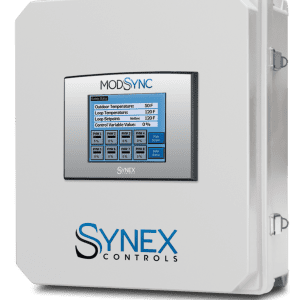

The equipment included four (4) Fulton VMP49.5 HP vertical firetube boilers, a 5,500 lb./hr. combination deaerator/flash tank including pumps and VFD’s, a blowdown separator, a chemical feed system and Synex (A Fulton Company) ModSync boiler room controller.

Once constructed and tested, the plant was transported to an oversized flatbed truck and transferred to a floating barge. The barge transported the plant via the East River to a site near the hospital where special rigging and cranes were able to transfer the plant from the barge to the hospital rooftop.

The system was calibrated and commissioned by ATI technicians where it now serves a vital role to the community.