Fulton

VSRT-250 Boiler

Fulton VSRT-250 Vertical Spiral Rib Tubeless Steam Boiler

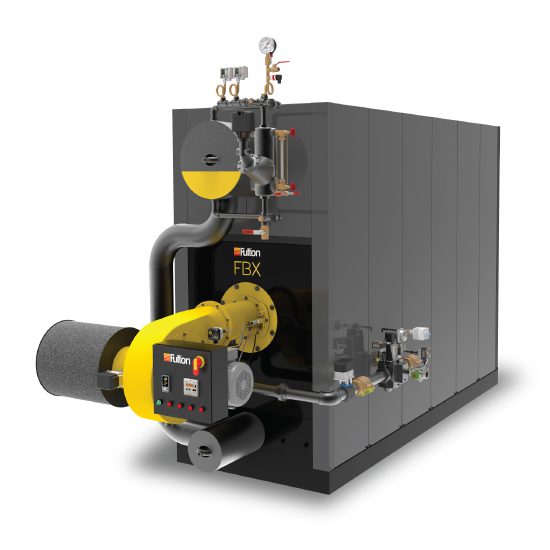

In 1949, Fulton pioneered the vertical tubeless design, which quickly became the industry standard for industrial steam boilers. Since that time, no one has been able to improve upon Fulton’s original design.

In 2018 Fulton raised the bar with the VSRT-250 Vertical Spiral Rib Tubeless Steam Boiler boiler, the world’s first fully wetted, refractory-free vertical tubeless boiler and the new standard for industrial steam boiler design.

VSRT boilers are built to last as a reliable source of clean steam, providing cost savings and operator peace of mind for years to come.

Prefabricated Engineered Assemblies

We offer custom prefabricated engineered assemblies (packaged skids and enclosures) with the purchase of any boiler, heating, cooling or water system. Manufactured in the USA, these military-grade platforms deliver stability, portability, protection and a smaller footprint for large-scale industrial equipment.